North Andover’s 6K is the recipient of a $1.5 million grant that will help the company recycle scrap materials and transform them into premium metal powder used in 3D printing.

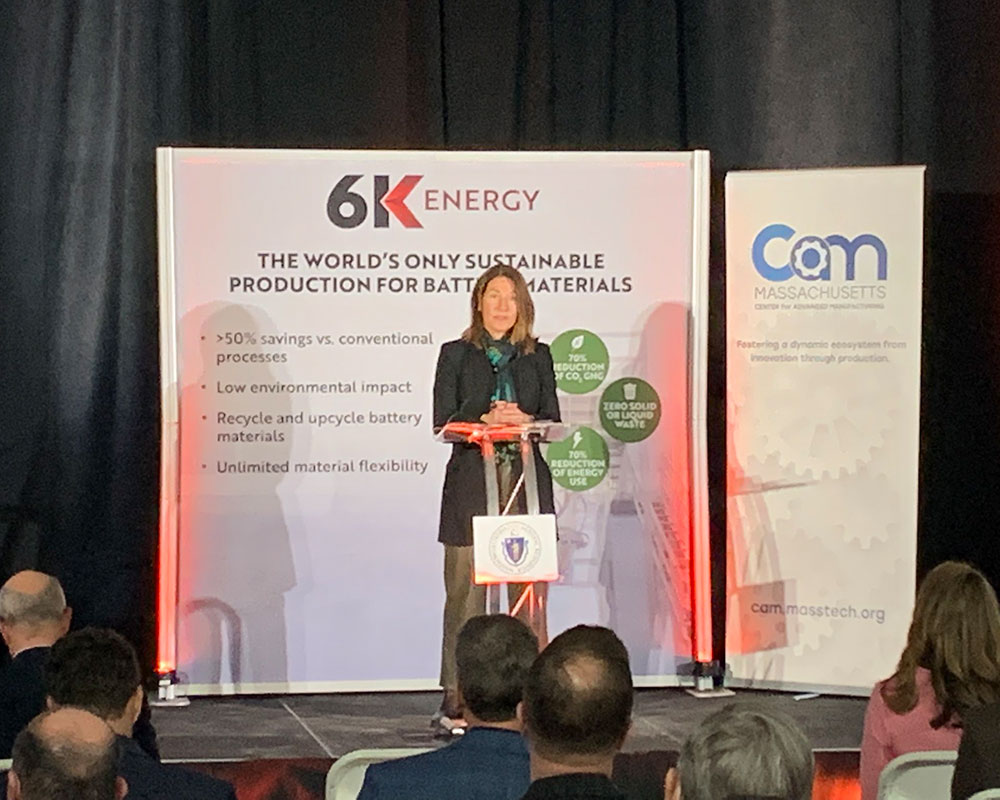

The grant, officially awarded during a ceremony Thursday at 6K’s new battery material production plant, comes from the Massachusetts Manufacturing Innovation Initiative. On hand were Lt. Gov. Karyn Polito and Housing and Economic Development Secretary Mike Kennealy. There was also an unveiling of plans for a new 33,000-square-foot battery center of excellence pre-production plant in North Andover. It will be one of the largest battery material production facilities in the United States.

The state grant pays for the purchase of one new UniMelt system, designed by 6K and built by Helfrich Brothers Boiler Works in Lawrence with components from AVS in Ayer. Officials said the three-way business connection highlights the strong in-state supply chain.

“The Commonwealth supported the growth of 6K through early investments made by MassDevelopment and we’re continuing that support with this new advanced manufacturing grant from the M2I2 program,” said Polito. “Massachusetts plays a critical role in technologies that are advancing our clean energy future, including electric cars. As students across Massachusetts look forward to their careers in STEM fields, it’s my hope that they’ll discover the ground-breaking innovations being produced by companies like 6K.”

Sen. Diana DiZoglio said “6K Inc.’s innovative technology has created sorely needed jobs in in the Merrimack Valley and bolstered efforts to reduce wastewater, greenhouse gas emissions and energy use.” Rep. Christina Minicucci added, “Not only is this North Andover-based business contributing to our community’s economic development, they are also committed to sourcing materials locally and keeping their supply chain dollars in Massachusetts whenever possible.”

Officials said the investment is a cost-competitive solution to traditional material manufacturing methods which take longer and tend to produce more pollutants and waste. By contrast, they said, the UniMelt system produces material in two to three seconds with no hazardous waste, a six-time reduction in water usage and a three-time reduction in both power use and CO2 emissions.